Booth Package

- Fan & Motor

- Exhaust Filters

- Solenoid Valve

- Nuts & Bolts

- Manometer

- Light Fixtures

- Assembly Instructions

- Door interlock hardware – Brixon Latches (for filtered door booths)

- Tubes or Bulbs

- Duct Package

- Sprinkler Systems

- Air Lines

- Electrical Switches

- Motor Starter

- Attachment Anchors from booth to floor

- Electrical Hook-up

- Conveyor Openings

- Explosion-Proof Motors

- Custom Sizing

- Powder coating of panels

NOTES:

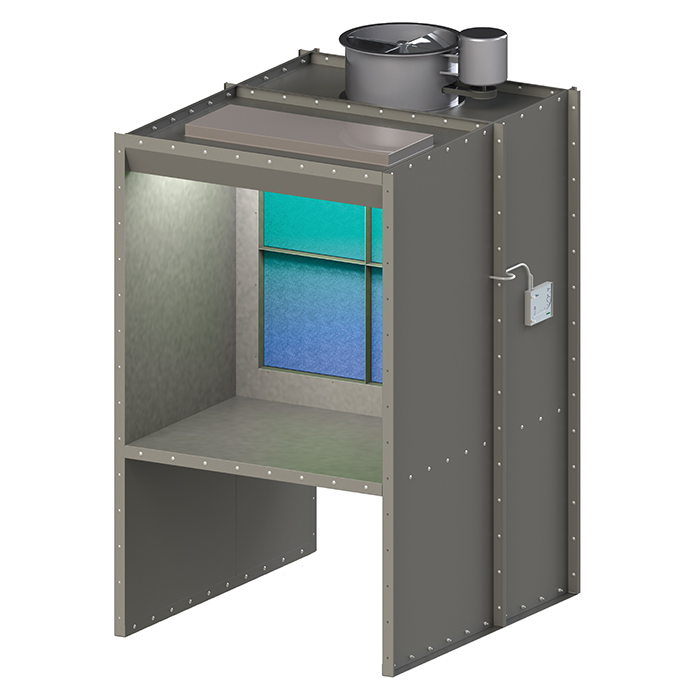

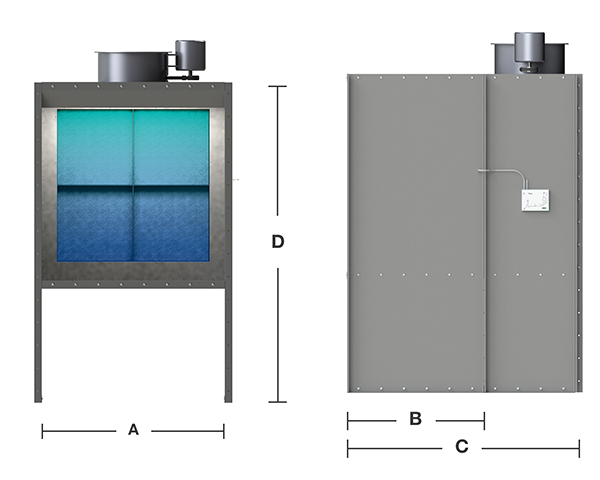

BENCH BOOTHS are used for coating small-parts and items. Best for moderate industrial painting that does not require high gloss finishes. Filtered front doors are optional; they enhance the quality of finished products in dusty conditions.

1

EXHAUST FILTERS

Various options available for exhaust filters: fiberglass, high efficiency, pocket type, and more. Depending on your process, your salesman will be able to give you the filter which best suits your filter needs.

2

FAN

Construction

- Non-sparking materials.

- AMCA Certified for air and sound

- Fabricated Aluminum Blades

Motor

- U.L. Listed

- 3-phase, 208/230/460 volt, 60Hz

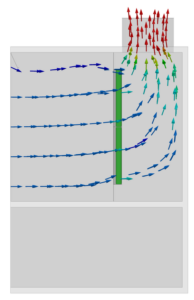

- Face Velocity exceeds 100 F.P.M. code requirement

- See specs for C.F.M. values per booth size

- Belt driven with enclosed belt guards

- Motor to include identification plate stating the ventilation rate for which the system is designed

Solenoid Valve

- Single Phase (voltage must be stated)

3

LIGHT FIXTURES

U.L. and C-U.L. approved. 120-volt Light Fixtures. Fluorescent and LED availableTypes

- Vapor- Tight (V.T.) for Class 1, Division 2 locations (National Electric Code and NFPA 70)

- Listed Open-Type (O.T.) fixtures

Mounting

- Placed on the outside of ¼” clear tempered (heat treated) glass, gasketed and locked into place at the working depth.

4